Height Adjustable Computer Desk

(my wheely desk)

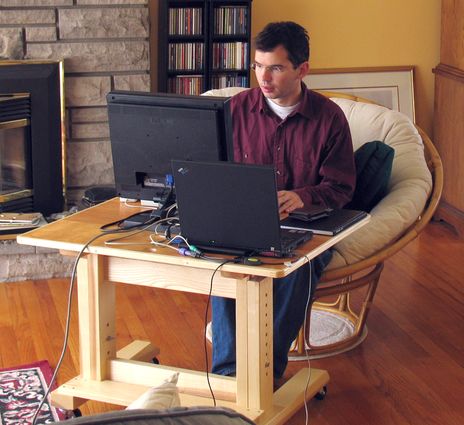

Me using the first height adjustable wheely desk I built. |

I came up with the design for a desk like this for the purpose of doing work from out of the office. I had a girlfriend in another city at the time, and in order to spend more time with her, I decided to “work from home” from her home with a laptop computer and external monitor for a little bit.

When working at the computer, it's important to me that I have a desk and chair that go well together ergonomically, so that I can sit comfortably for hours and focus on my work without distractions. I didn’t want to go out of way to buy a nice ergonomic Herman Miller “Aeron” office chair like they have at work. Instead, I decided that a variety of seats could be quite comfortable and ergonomic, if the desk was at the right height to go with it. For example, a couch, with pillows behind the back be quite "configurable" and comfortable for long stretches, but not when used with a normal desk of approximately 72 cm height.

So I decided to build a height adjustable small computer ‘desk’ so that I could take it there, and adjust it to whatever was optimal to go with the chosen seating option – whether it be a couch, a chair, or whatever.

I also wanted to be able to put the desk out of the way in the evening, so I built it with wheels, and sized it such that it could still be rolled down a hallway and through a doorway.

After I built the original desk, it was still a couple of weeks until my next trip to her, so I tried it out at my house, and put my computer on it. I found that I quite liked it. I'd sit on my day bed with a pile of pillows behind me, and then pull the computer desk up to me. Once I left the desk at her place, I decided to build a second one to use with my computer at home.

So I started building a second computer desk like that. The first one was built with nice white ash as material, but I used up all the white ash I had lying around. The second one I built mostly of spruce, which can be obtained as construction lumber relatively cheaply. You can get pretty decent spruce if you are careful about selecting it. It also helps to buy wider material – such as 2x8’s, because those come from larger trees and will typically not be as full of small knot holes and will have straighter grain.

|

|

As usual though, I didn’t draw any plans for this piece of furniture. But the pictures above should be useful for you to figure out what overall dimensions. I took them from far away and straight on, so there is relatively little perspective distortion. You should be able to just print the pictures, and work out the scale. For reference, the desk is set to 57.5 cm high. The top is 85 cm wide and 62 cm deep. The monitor on the desk is an 18” LCD monitor, which is 24 cm wide on the outside. The row of holes for adjusting the height is spaced at 3 cm intervals. The holes on the inside parts of the legs are spaced at 4.5 cm, which allows for height adjustment steps of 1.5 cm by using different combinations of holes.

| Legs reversed for storage |

| Fully disassembled |

The bracket that ties the legs together on the bottom rear is made of maple. It's the top

of the two brackets in the above photo. Making it out of spruce would have meant making it

a fair bit thicker. The other bracket goes between the two top leg segments. It's responsible

for side to side stability of the desk. The cross beam is mortised into the vertical parts

of that bracket, although I'm sure doweling would work good enough also.

This picture shows the two leg segments. the top part screws to the plywood top. The two pieces

shown are the bottom right segment, and the top left segment - these two don't actually

mesh together in the normal position, but picture the top part being a mirror image of itself,

mirrored against the plane that is the floor, and you can see how it meshes with the bottom part.

Also note that I mortised the T-joints. Strength is critical for these, especially

if somebody stands on the desk. Four dowels 3/4" inch in size instead should hold it too.

The upright part of the legs with the slots is made of maple for strength.

It's 12 cm wide, and with five slots across, that makes the slots and ridges each 1.2 cm wide.

I would use four slots instead of five if I was

building it again. This would make the individual redges between the slots stronger, and also be

a bit less work to make.

An important detail is that the bottom part of the legs has the slots sticking out with respect to the bottom cross piece with the wheels on it. That way, the grooved part from the top can slide down beyond the slots on the bottom part, so that it can extend down far enough to almost touch the floor.

This picture above gives a better idea of how the parts of the frame fit together.

Another afterthought was to oil the castors. They come with a little bit of grease on

the ball bearings, but both the swivel and the wheel turn easier and quieter with a drop of oil on

them. Seeing that I always pull the desk up to myself after I sit down, this helps a lot.

I have been using this desk now for two years, and I'm not at all tempted to go back to using a conventional desk. I have it in front of a daybed that I built, where I can pile an assortment of pillows behind me, giving me all kinds of comfortable, ergonomic, as well as slouching configurations. Its also a great setup to be using a computer together with somebody, as the daybed allows two people to sit comfortably side by side. Below is a non-posed shot of the desk in typical use. Sitting cross legged on the daybed seems to be a popular choice as well.

Also makes a great laptop computer desk, or just general work table for jobs where you need to have your elbows above the table. Its been suggested it would make a good table for sewing or quilting.

Got published in a magazine!

Got published in a magazine!

Some time last year, woodcraft magazine approached me about writing an article about how to build one of these pieces of furniture. The article was published in the March issue of Woodcraft Magazine. To get enough detail photos of the construction, I had to build another one. The article ended up covering 7 pages, including 40 illustrations. That was a fun and different thing to do. If you are a magazine publisher, and would like me to write an article for your magazine, just drop me a line.

Read the Woodcraft Article on my website.

To my Woodworking website or to the Woodwork projects index.