3" caliber refined 'Product Launcher' Cannon

With the popularity of the previous "product launching" event in 2002, I organized another such event for June 2003. I built an improved version of my "product launcher" for the occasion.

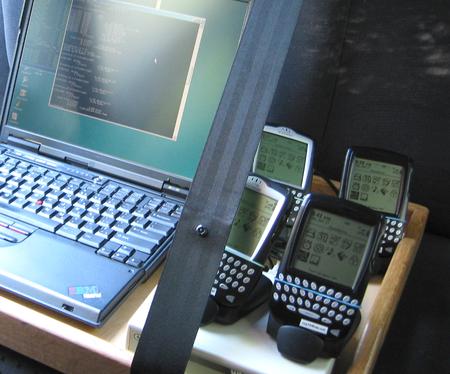

A difference this time was that the newer BlackBerry products

were just a tiny bit narrower than the old models, so I was able

to reduce the cannon's caliber to 3 inches.

A difference this time was that the newer BlackBerry products

were just a tiny bit narrower than the old models, so I was able

to reduce the cannon's caliber to 3 inches.

The photo at left is the best I could dig up of that product after many years. I took that photo of a drive test data-logging set-up in the back of my car

There were a few weaknesses in my 4-inch cannon that I wanted to address:

- The 4" barrel eventually split open

- The 2" cleanout plug on the back could not withstand the pressure o firing

- I wanted a combustion chamber bigger than the barrel

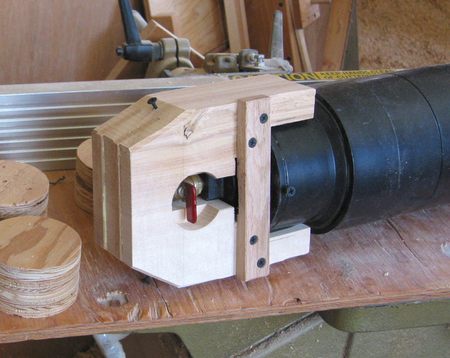

Design and Construction

For extra strength, I made the combustion chamber of the new cannon out of very short

pieces of 4" ABS pipe, joined together with connecting pieces. The joining part

goes around the pipe, so where it is joined, the pipe wall is twice as thick. With the joining

pieces touching each other, the entire combustion chamber had walls double the thickness.

Of course, along its axis, this arrangement has some weakness between the connectors,

but the 'hoop stress' (around the circumference) of a pressure cylinder is twice what

the stress is along it's axis. That's why when pipes rupture from pressure, they always

crack along the length of the pipe.

For extra strength, I made the combustion chamber of the new cannon out of very short

pieces of 4" ABS pipe, joined together with connecting pieces. The joining part

goes around the pipe, so where it is joined, the pipe wall is twice as thick. With the joining

pieces touching each other, the entire combustion chamber had walls double the thickness.

Of course, along its axis, this arrangement has some weakness between the connectors,

but the 'hoop stress' (around the circumference) of a pressure cylinder is twice what

the stress is along it's axis. That's why when pipes rupture from pressure, they always

crack along the length of the pipe.

To avoid the weakness of the 4" plug, this time around, I used a 4" to 3" adapter, and then a 3" to 1.5" adapter (I couldn't find a 4" to 1.5" adapter) I figured the 1.5" plug should be able to withstand more pressure than the 2" plug. I hadn't had a 1.5" plug fail on me yet.

I wrapped some steel wire around the part with the plug in it so that the outside

threads could, hopefully, not expand as much and not let go of the 1.5" plug.

I also wrapped the wire

around the end of the 3" barrel near the combustion chamber. I figured the

part nearest the combustion chamber would be most vulnerable. The further from the

chamber, the gas will have already expanded before it gets there, so there

would be less pressure.

I wrapped some steel wire around the part with the plug in it so that the outside

threads could, hopefully, not expand as much and not let go of the 1.5" plug.

I also wrapped the wire

around the end of the 3" barrel near the combustion chamber. I figured the

part nearest the combustion chamber would be most vulnerable. The further from the

chamber, the gas will have already expanded before it gets there, so there

would be less pressure.

As an extra measure, I made a hardwood bracket to fit around the breech. This was designed to provide even support against the cannon's recoil, especially against the 1.5" cleanout plug, to further prevent it from coming out.

Testing

As with my previous cannon, I used a mixture of about 80% oxygen and 20% MPS gas for fuel. On a previous event that mixture proved to be quite potent.I tested the cannon by firing a full coke can out of the barrel. A can of coke is a fair bit heavier than the Blackberries I planned to launch, so if the cannon didn't self-destruct firing that, it should be ok for the BlackBerry..

The coke can didn't hold up too well. The force of acceleration caused the bottom

of the can to rupture and expand to the full 3" diameter of the cannon.

Out of the cannon came a spray of coke, and an empty shredded can which didn't

fly too far. The remains of the can fit snugly in the 3" barrel. The top of

the can was undamaged, not even the pop tab had opened.

The coke can didn't hold up too well. The force of acceleration caused the bottom

of the can to rupture and expand to the full 3" diameter of the cannon.

Out of the cannon came a spray of coke, and an empty shredded can which didn't

fly too far. The remains of the can fit snugly in the 3" barrel. The top of

the can was undamaged, not even the pop tab had opened.

The wooden plug, which I put behind the coke can, held up quite well. The twisted

cloth seal I put in the grove must have worked fairly well, because only the part of the

plug behind the seal was blackened from the firing. The blue cloth extending from the plug

is intended as a bit of a drag chute, and to make it easier to find. The plug ended

up flying about ten times as far as the shredded can.

The wooden plug, which I put behind the coke can, held up quite well. The twisted

cloth seal I put in the grove must have worked fairly well, because only the part of the

plug behind the seal was blackened from the firing. The blue cloth extending from the plug

is intended as a bit of a drag chute, and to make it easier to find. The plug ended

up flying about ten times as far as the shredded can.

The Launching event

We started out by launching product into the air. Problem with that is that it is very difficult to locate the test specimen. Somewhere out in that farmers field is some moderately damaged piece of handheld electronics. I added a blue strip of plastic to make the unit under test easier to locate, but even then, finding the results required a team effort!

Here's Kent Nickerson, having just found

the blackberry and the plug. But we couldn't find all the units, so somewhere in the

pasture is a moderately damaged BlackBerry.

Here's Kent Nickerson, having just found

the blackberry and the plug. But we couldn't find all the units, so somewhere in the

pasture is a moderately damaged BlackBerry.

It's kind of inefficient to shoot into the air. Most of the momentum is harmlessly

burned off as drag. And even then, then there's no guarantee the device will

land on anything hard. Its much better to have the impact

zone as close to the muzzle as possible.

Here you can see a typical test setup. The cannon is supported by several pieces of

firewood. Behind the breech is a heavy (15 kg) steel weight to absorb some of the

recoil. At right is a 1" thick steel plate, propped up with some firewood.

For scale, the thin part of the barrel is 6 feet (1.5 meters) long.

Here you can see a typical test setup. The cannon is supported by several pieces of

firewood. Behind the breech is a heavy (15 kg) steel weight to absorb some of the

recoil. At right is a 1" thick steel plate, propped up with some firewood.

For scale, the thin part of the barrel is 6 feet (1.5 meters) long.

The results were quite good. Except for the plastics, which can deform a lot without breaking,

the Blackberry devices ended up in fragments about the size of a quarter.

The results were quite good. Except for the plastics, which can deform a lot without breaking,

the Blackberry devices ended up in fragments about the size of a quarter.

The results are always fascinating!

The results are always fascinating!

We also fired a few 3" caliber cans of vegetables. 3" is a very

common caliber for canned goods, and the cans fit very snugly down the barrel.

The first can we shot was at a 45 degree angle, and we weren't able to find it.

It's somewhere in the field now.

We also fired a few 3" caliber cans of vegetables. 3" is a very

common caliber for canned goods, and the cans fit very snugly down the barrel.

The first can we shot was at a 45 degree angle, and we weren't able to find it.

It's somewhere in the field now.

The second vegetable can was shot at the steel plate. We expected this to be quite messy, but with the steel plate angled up slightly, the vegetables were dispersed so finely that we couldn't find a trace of them, save for some small bits of mashed carrot on the can. It was also interesting to see the can rip in so may places.

Some findings...

Despite the bracket on the back, and the wire wrapped around the outside of the thread, and the use of a 1.5" plug instead of a 2" plug, the plug still ended up slipping its threads. This suggests that the MPS gas makes for a much more powerful explosion than propane or propylene I ued on my first cannon

This canon also didn't produce very large fireballs at the muzzle and wasn't as loud as I expected. I'm guessing that most of the energy was used for accelerating the BlackBerry. In fact, on some shots, the sound of the 'ping' against the steel plate was more prominent than the bang from firing the cannon.